Equipment

We have Purchased three main equipment

FIRST:

The universal processing system (RoboQbo 70) Perfect, even, extremely rapid cooking that is delicate at the same time, capable of preserving the nutritional properties in foods thanks to the APS heating system (Advanced Power Steam). Ultra-rapid product concentration processes, carried out in just a few minutes, saving literally hours of time when compared to traditional systems. Results of extraordinary quality with strongly enhanced aromas and unaltered natural colors.

PERFORMANCE:

Extremely fast heating, programmable, modular, maintainable, in vacuum, pressure or both up to 120°C • the main cooker, it is one of the most efficient machines, it cooks with both high pressure and vacuum, the whole production process is reduced into one cycle

SECOND:

Micron Ball Refiner: The Micron ball refiner is designed for the production of spreadable creams, anhydrous pastes for ice creams, and cream sweets. The machine is equipped with a refrigerator with the purpose of regulating, within the set limits, the excess heat caused by the friction generated between the spheres. Thus, it preserves unaltered the organoleptic qualities of the product.

The circulation of the product during refinement is maintained by a dual-purpose volumetric pump. The refining cylinder is also regulated to maintain a warm temperature to prevent the fatty residues between the balls from solidifying during pauses in the working cycle.

THIRD:

The BATH PASTEURIZER WP 200 The content of the bath pasteurizer is heated by two heating elements in a water bath. The bottles are placed on the grid above. and heated to the set temperature. Through the direct heating of the water basin, a high effectiveness is achieved. In conjunction with the temperature control, a constant processing temperature is guaranteed.

premises and infrastructure

We have Purchased three main equipment

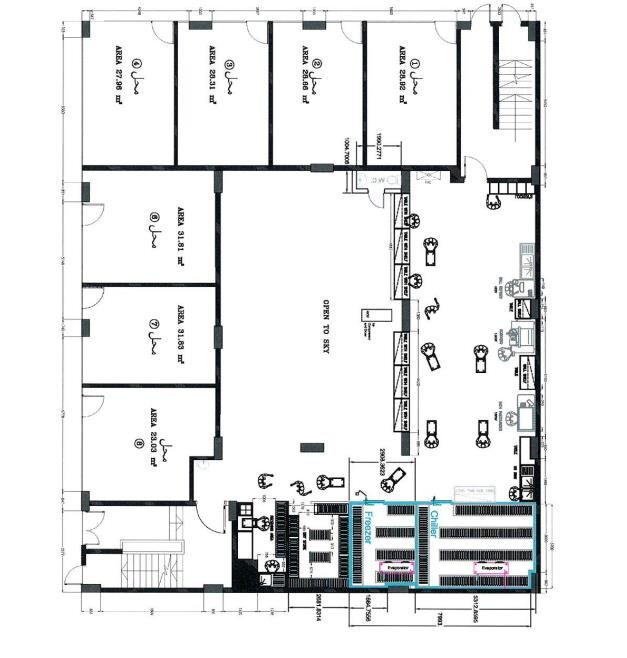

The Location of the mill is in the Qurain restaurants area, the area is 249 square meters, 160 square meters for Operation and the rest is for the dry storage, below is the layout of the premises:

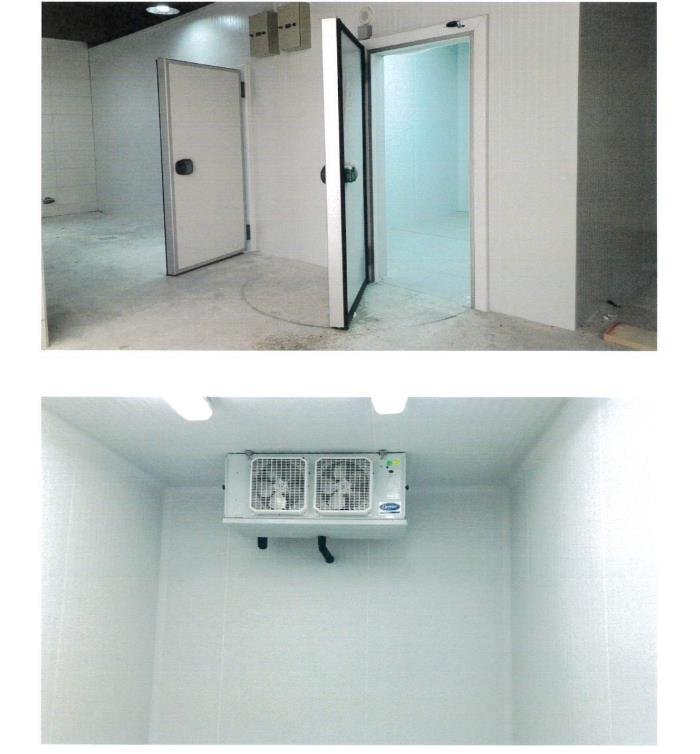

The premises have been Equipped with a 3.7m X 5m walk in chiller and 3.7m X 3m Walk in Freezer.

An Ingersoll Rand, 10 Bar, 200 Liters/h screw compressor equipped with a dryer and filters has been fitted to deliver compressed air to the Ball refiner, the compressor is one of the high-end compressors with a very low decibel.

The compressor and dryer are mounted on a steel base, fabricated.